- Posted on: 2021-08-10

When it comes time to buying test equipment for automation, clients often only look at the technical specifications of the hardware and the price. Unless experienced engineers have gone through the pain previously, little consideration is given to the ease of communication and the reliability of that communication from the control computer.

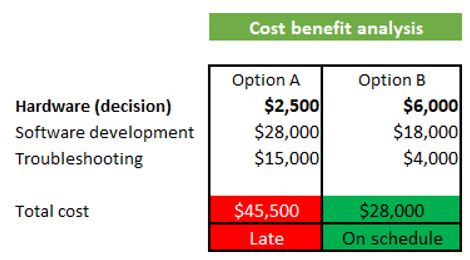

Sadly, this can be a very expensive mistake in many cases. This also has a huge impact on the development because bugs are not always easy to isolate, reproduce and in some cases, they are impossible to fix without changing the hardware itself. What this means is that many companies go through the trouble of saving $100 only to waste 100 hours of their engineer’s time to make them work properly.

A mistake too common…and expensive

A savings on hardware often leads to much higher costs laterDoes this sound familiar? Has it happened to you before? We have countless stories, but one that happened recently was around a CAN device. CAN is a communication protocol and widely found in automotive and energy applications. On paper, every USB-CAN transceiver is identical so why are some $200 while others are $700, excluding features such as onboard logging.

In our example, the client asked to use a non NI CAN product and said there were “some LabVIEW drivers” on the manufacturer’s website. Those did work initially, but within a week, they had already cost our clients more.

Why? Many different reasons exist including:

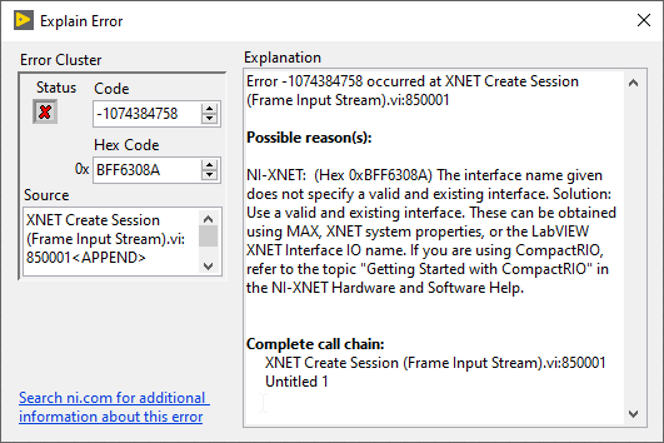

- Some frames were not making it to the bus

- Some frames were not received without any warning

- At random times, their “driver” (dll wrapper) would hang the application for a few seconds

It took us some more time to demonstrate those to the client but, in the end, they switched to the NI XNET devices and drivers.

Benefits of high-quality drivers

NI has many great example of how high quality software drivers greatly reduce costs and makes the final solution much more reliable. XNET and DAQmx are two such examples that truly help by:

- Offering deterministic performance

- Lowering CPU load by pre-processing on the hardware and DMA transfers

- Reporting extremely detailed software exceptions (error cluster) to the developer

In conclusion

Next time you need to make a decision about a piece of hardware for a test system, make sure to ask yourself if saving $200 or even $1,000 is really worth the time required to test and validate the drivers. Often this time spent on the drivers is 5-10x the price difference in hardware. NI is not the only company offering DAQ equipment that has great drivers but the “cheap hardware options” most often don’t. Do you want to spend your time validating the equipment manufacturer’s drivers or do you want them to do that for you?